You wouldn't download a car?

Well in fact you already can, Honda have released

free downloadable models

of miniature versions of their cars to print out at home.

A company made a full sized car that can be printed in

less that 2 days

3D Printed Car -

It is made from ABS plastic that has been reinforced with carbon fiber.

Everything on the car that could be integrated into a single material piece has been printed.

The mechanical components of the vehicle,

are sourced from Renault’s Twizy, an electric powered city car.

and should be drivable on US roads in 2015 and recently a

Chinese company 3D printed a full-size

Working Car

3D Printed Car -

It is made from ABS plastic that has been reinforced with carbon fiber.

Everything on the car that could be integrated into a single material piece has been printed.

The mechanical components of the vehicle,

are sourced from Renault’s Twizy, an electric powered city car.

and should be drivable on US roads in 2015 and recently a

Chinese company 3D printed a full-size

Working Car

3D Printed Car -

“The density of the material is much lighter than that of the metal,

only one-seventh or one-eighth,” explains Chief Designer Chen Mingqiao.

“Lighter weight will help save energy in the future.”

for just $1770.

3D Printed Car -

“The density of the material is much lighter than that of the metal,

only one-seventh or one-eighth,” explains Chief Designer Chen Mingqiao.

“Lighter weight will help save energy in the future.”

for just $1770.

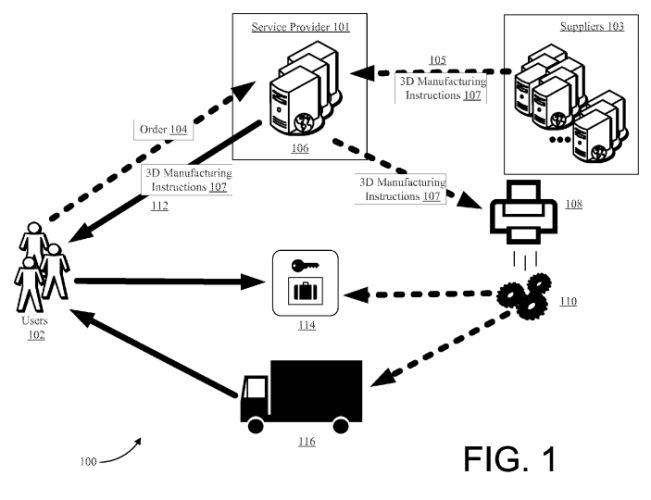

3D printer technology is improving quickly and is set to disrupt

manufacturing even further, products will not have to be transported

thousand of miles to reach you, 3D printer allows items to be manufactured locally.

3D printing of food is now possible such as

pizza

3D Printed Pizza -

Founded in 2013, XYZprinting is a global company with the goal of bringing affordable 3D

printing to businesses as well as individual consumers. They had a ton of different models

of printers on display at CES, but the one that got us all riled up was their Food Printer.

,

cookies

3D Printed Cookies -

The Food Printer turns ingredients into uncooked food. The ingredients can be chocolate or dough or a

combination of solid items and the results, for now, will be cookies, or

decorations for cakes. You then do need to bake the printed items before you can consume them, however.

and

chocolate

3D Printed Chocolate -

“We are now using 3D technology to bring Hershey goodness to consumers in unanticipated and exciting ways. 3D printing gives

consumers nearly endless possibilities for personalizing their chocolate, and we look forward to

continued development of this amazing technology.”

Imagine a future where we have robot

personal

robot chefs

or robot

bartenders

3D Printed Chocolate -

“We are now using 3D technology to bring Hershey goodness to consumers in unanticipated and exciting ways. 3D printing gives

consumers nearly endless possibilities for personalizing their chocolate, and we look forward to

continued development of this amazing technology.”

Imagine a future where we have robot

personal

robot chefs

or robot

bartenders

/cdn0.vox-cdn.com/uploads/chorus_asset/file/2476670/15807514645_e781c9e980_o-2040.0.jpg) Robot Bartenders -

The two robots are perfectly efficient, fast bartenders. They always select the perfect amounts of Bulleit borboun,

ice, and lime, and shake it just so before dumping it

carefully into my plastic cup. They move in fluid, full gestures, almost as if they're human.

making whatever we desire on demand, and even

feeding us

if we get to Wall-E levels of slothfulness.

Clothes can be printed, Nike has made 3D printable

trainers,

a fashion company designs 3D printed dresses which

flow like fabric

and even

leather

Robot Bartenders -

The two robots are perfectly efficient, fast bartenders. They always select the perfect amounts of Bulleit borboun,

ice, and lime, and shake it just so before dumping it

carefully into my plastic cup. They move in fluid, full gestures, almost as if they're human.

making whatever we desire on demand, and even

feeding us

if we get to Wall-E levels of slothfulness.

Clothes can be printed, Nike has made 3D printable

trainers,

a fashion company designs 3D printed dresses which

flow like fabric

and even

leather

Lab Grown Leather -

The project is early in development, she said, and right now they are just testing as many materials as possible,

such as silk, pearls, and nylon to see how the cells interact with them, as well as experimenting with growing two

different materials concurrently on one scaffold with the aim of creating unique hybrids.

She said this has important implications for the future of animal products.

is trying to be grown in labs.

The

Voxel8

Lab Grown Leather -

The project is early in development, she said, and right now they are just testing as many materials as possible,

such as silk, pearls, and nylon to see how the cells interact with them, as well as experimenting with growing two

different materials concurrently on one scaffold with the aim of creating unique hybrids.

She said this has important implications for the future of animal products.

is trying to be grown in labs.

The

Voxel8

Embedded Electronics -

Voxel8, a printer presented at CES that makes it much easier to blend plastic,

conductive ink and other electronic components in the same

object to manufacture highly customizable devices, such as your very own quadcopter.

3D printer can blend plastics and electronics in the same printed object.

Solar panels

Embedded Electronics -

Voxel8, a printer presented at CES that makes it much easier to blend plastic,

conductive ink and other electronic components in the same

object to manufacture highly customizable devices, such as your very own quadcopter.

3D printer can blend plastics and electronics in the same printed object.

Solar panels

Solar panels -

A printer has been able to

make prototypes of the solar cells in order to improve their efficiency.

The technology consists of a type of “solar ink” which is designed to capture

sunlight and turn it into electricity.

Solar panels -

A printer has been able to

make prototypes of the solar cells in order to improve their efficiency.

The technology consists of a type of “solar ink” which is designed to capture

sunlight and turn it into electricity.

A fine layer of this ink is then deposited onto a material, such as plastic.

This allows for cells to be embedded into windows to generate electricity or to be used to charge devices such as smartphones and laptops.

can even be printed and many, many

other objects

including even

3D printers.

3D printers -

RepRap takes the form of a free desktop 3D printer capable of

printing plastic objects. Since many parts of RepRap are

made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself

3D printers -

RepRap takes the form of a free desktop 3D printer capable of

printing plastic objects. Since many parts of RepRap are

made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself

3D printers, modelling and 3D scanning tools facilitate the process to design and manufacture

whatever you can imagine, this will

lead to many new useful and artistic creations for the world as more people gain

access to modelling tools and gain the ability to design, create and

share

their ideas for free.

Prices of 3D printers are

falling fast,

printer Prices -

It is possible today to get low-end, relatively basic printers for several hundred dollars,

where in the past they started in the thousands-of-dollars range.

Canalys expects the 3D printer market to grow rapidly in the coming years,

with sales of printers, materials and services reaching $3.8 billion this year,

compared to $2.5 billion last year, and hitting $16.2 billion by 2018.

allowing more people to be able to afford them.

It took the 3D printing industry 20 years to reach $1 billion in size.

In five additional years, the industry

generated

its second $1 billion.

It is expected to double again, to $4 billion, in 2015.

With 2D printer

ink

being incredibly overpriced, people have the right to weary of the cost of the

“ink” for the 3D printers. The plastic that lot’s of household 3d printer use could be extracted by

recycling

Recycling Plastic -

Three engineering physics students at the University of British Columbia have

developed a desktop plastic recycler and extruder that turns plastic waste into

the material needed for 3D printing

plastic bottles.

As Mining starts to use more

automation

Recycling Plastic -

Three engineering physics students at the University of British Columbia have

developed a desktop plastic recycler and extruder that turns plastic waste into

the material needed for 3D printing

plastic bottles.

As Mining starts to use more

automation

Automated Mining -

Robots may hold the key to preventing an industrial crisis in a country whose

geography makes many key jobs undesirable. The company is working to automate

its drilling and crushing as well as the dozens of mile-long trains that ship

nearly a million tonnes of iron ore to the coast each day.

for safety and cutting on labour costs then the price to extract metals and

minerals from the ground could becomes cheaper.

Automated Mining -

Robots may hold the key to preventing an industrial crisis in a country whose

geography makes many key jobs undesirable. The company is working to automate

its drilling and crushing as well as the dozens of mile-long trains that ship

nearly a million tonnes of iron ore to the coast each day.

for safety and cutting on labour costs then the price to extract metals and

minerals from the ground could becomes cheaper.

There is lots of research going into 3D printing to make the process better, cheaper and faster.

A recently unveiled 3D printer using technology called

CLIP

CLIP -

Continuous Liquid Interface Production is a breakthrough technology that grows

parts instead of printing them layer by layer. CLIP allows businesses to

produce commercial quality parts at game-changing speeds, creating a clear path to 3D manufacturing.

which offers 25 to 100 times speed

improvements over traditional 3D printing, which can takes hours or even days to finish.

Other new innovations are coming out such

as being able to print using the incredibly strong and conductive material

Graphene,

Graphene Printing -

Graphene 3D is excited to begin offering Conductive

Graphene Filament directly to customers and opening

new avenues of creation for 3D printer users

and techniques known as

4D printing,

where researchers can print out dynamic 3D structures capable of changing their shapes over

time are improving, they could one day be used in everything from medical implants to home appliances.

Graphene Printing -

Graphene 3D is excited to begin offering Conductive

Graphene Filament directly to customers and opening

new avenues of creation for 3D printer users

and techniques known as

4D printing,

where researchers can print out dynamic 3D structures capable of changing their shapes over

time are improving, they could one day be used in everything from medical implants to home appliances.

Cheap as Chips

Robots are getting cheaper, the total cost of owning and operating an advanced robotic spot welder has plunged 27 percent, Cheaper Robots - Robots presently perform only 10% of manufacturing tasks, but that is expected to rise to 25% by 2025 as robots become more affordable and able to perform more tasks. “Within five to 10 years, the business case for robots in most industries will be compelling, even for many small and midsized manufacturers,” from an average of $182,000 in 2005 to $133,000 in 2014, the price is forecast to drop by a further 22 percent by 2025. By 2025, the widespread adoption of advanced industrial robots will boost manufacturing More Productivity and Less Labour Cost's - BGC estimates that this widespread adoption of robots could cut manufacturing labour costs in the world’s 25 largest goods-exporting nations by an average of 16% more than would otherwise be the case. Output per worker could rise by 10–30% above productivity gains generated by other measures. productivity by up to 30% in many industries, and cut labour costs by 18% or more. As robots get cheaper and better they can be used to build other robots, even themselves, cutting down the future manufacturing costs substantially.

Robots are getting so much cheaper that they are even

replacing

workers in

China.

Robots to Power New Wave of Productivity -

“In China, one of the world’s largest markets for robots, greater use of automation could compensate

for a significant part of the loss in cost competitiveness that is expected

to result from rapidly rising factory wages and the growing challenge of finding manufacturing workers”.

Many Chinese manufactories are looking to replace their workers with

robots,

Robots to Power New Wave of Productivity -

“In China, one of the world’s largest markets for robots, greater use of automation could compensate

for a significant part of the loss in cost competitiveness that is expected

to result from rapidly rising factory wages and the growing challenge of finding manufacturing workers”.

Many Chinese manufactories are looking to replace their workers with

robots,

Robots Leave Behind Chinese Workers -

The government of Guangdong Province, the heart of China's manufacturing behemoth,

announced a three-year program to subsidize the purchase of robots at nearly 2,000

of the province’s -- and thus, the world’s -- largest manufacturers.

Guangzhou, the provincial capital, aims to have 80 percent of its factories automated by 2020..

Foxconn the manufacturing giant employs over 1 million workers

in mainland China and in Feb 2015 the

company CEO

expressed his desire to

use robots and automation to complete 70 percent of its assembly line work in 3 years time.

The largest market for robotic technology is now China, with wages increasing

and labour force decreasing lots of manufacturing companies in China are planning to

replace

Cheaper Robots, Fewer Workers -

Faced with an acute and worsening shortage of blue-collar workers,

China is rushing to develop and deploy

a wide variety of robots for use in thousands of factories.

Robots Leave Behind Chinese Workers -

The government of Guangdong Province, the heart of China's manufacturing behemoth,

announced a three-year program to subsidize the purchase of robots at nearly 2,000

of the province’s -- and thus, the world’s -- largest manufacturers.

Guangzhou, the provincial capital, aims to have 80 percent of its factories automated by 2020..

Foxconn the manufacturing giant employs over 1 million workers

in mainland China and in Feb 2015 the

company CEO

expressed his desire to

use robots and automation to complete 70 percent of its assembly line work in 3 years time.

The largest market for robotic technology is now China, with wages increasing

and labour force decreasing lots of manufacturing companies in China are planning to

replace

Cheaper Robots, Fewer Workers -

Faced with an acute and worsening shortage of blue-collar workers,

China is rushing to develop and deploy

a wide variety of robots for use in thousands of factories.

So although building robots to replace workers is seldom cheap,

a growing number of companies are finding it less costly than either

paying ever-higher wages in China or moving to another country.

workers with robots,

China will have more robots operating in its production plants by 2017 than any other country.

The growth of robot sales is

increasing,

More Productivity and Less Labour Cost's -

Between 2008 and 2013 during the financial crisis the average robot sales increase

was at 9.5% per year, in 2013 about 70% of the total robot sales in 2013 were in Japan, China,

the United States, Korea and Germany.

from 2015 to 2017, robot installations are estimated to increase by 12% on average per year.

It’s not just industry and manufacturing robots that are becoming more accessible to purchase,

The market for consumer and office robots will

grow

More Productivity and Less Labour Cost's -

Between 2008 and 2013 during the financial crisis the average robot sales increase

was at 9.5% per year, in 2013 about 70% of the total robot sales in 2013 were in Japan, China,

the United States, Korea and Germany.

from 2015 to 2017, robot installations are estimated to increase by 12% on average per year.

It’s not just industry and manufacturing robots that are becoming more accessible to purchase,

The market for consumer and office robots will

grow

Robot Growth -

The consumer/office robot market is currently led by three distinct categories:

home cleaning and maintenance, “telepresence” (i.e., telecommuting to events or remote offices),

and advanced robots for home entertainment.

There will be a $1.5 billion market for consumer and business robots by 2019.

the most at a rate of 17% a year between 2014 and 2019.

Robot Growth -

The consumer/office robot market is currently led by three distinct categories:

home cleaning and maintenance, “telepresence” (i.e., telecommuting to events or remote offices),

and advanced robots for home entertainment.

There will be a $1.5 billion market for consumer and business robots by 2019.

the most at a rate of 17% a year between 2014 and 2019.

Computer technology has been following

Morse Law

, this has meant that computers

have been getting exponentially more powerful as well as continually shrinking in price and size,

this is helping to drive the ever increasing advance in robots capabilities and affordability.

Smart Robots

Robots are getting easier to operate, one example is Rethink Robotics smart collaborative robot Baxter. Baxter -

Baxter is a proven solution for a wide range of tasks – from line loading and machine tending,

to packaging and material handling. If you walk the floor of your facility and see

lightweight parts being handled near people, you’ve likely just found a great job for Baxter.

Baxter -

Baxter is a proven solution for a wide range of tasks – from line loading and machine tending,

to packaging and material handling. If you walk the floor of your facility and see

lightweight parts being handled near people, you’ve likely just found a great job for Baxter.

- Baxter is safe to operate next to in production environments. The sensors around its head give Baxter the ability to adapt to its environment. It is smart enough to know that it cannot continue with its job if it drops a tool.

- Baxter is flexible for a range of applications and re-trainable across lines and tasks, It’s manually trainable by in-house staff, no traditional programming is required.

- Baxter’s $25,000 base price is affordable, and its performance keeps improving through regular software releases. In 2014 it completed the same task almost 3 times faster versus the 2013 version of the software.

Sawyer -

“Together, Baxter and Sawyer can address many of the estimated 90 percent

of manufacturing tasks that cannot be feasibly automated with traditional solutions today,”

which is a smaller, lighter Baxter with a higher-precision hand.

Microsoft researchers claim that they have developed the first computer

system capable of

outperforming

humans on a popular benchmark.

Many companies are researching and competing to have the best

Computer Vision,

this means is

only going to get better and computers are even beginning to

understand

Sawyer -

“Together, Baxter and Sawyer can address many of the estimated 90 percent

of manufacturing tasks that cannot be feasibly automated with traditional solutions today,”

which is a smaller, lighter Baxter with a higher-precision hand.

Microsoft researchers claim that they have developed the first computer

system capable of

outperforming

humans on a popular benchmark.

Many companies are researching and competing to have the best

Computer Vision,

this means is

only going to get better and computers are even beginning to

understand

Understanding Vision -

Computer vision expert Fei-Fei Li describes the state of the art —

including the database of 15 million photos her team built to "teach"

a computer to understand pictures — and the key insights yet to come.

images,

Sawyer

Understanding Vision -

Computer vision expert Fei-Fei Li describes the state of the art —

including the database of 15 million photos her team built to "teach"

a computer to understand pictures — and the key insights yet to come.

images,

Sawyer

Sawyer Vision -

Sawyer offers an embedded vision system, with a head camera for wide view

applications and a Cognex camera in its wrist

that will eventually support many complex vision tasks.

and other

smart robots

will be getting better all the time thanks to improvements in Artificial Intelligence.

Sawyer Vision -

Sawyer offers an embedded vision system, with a head camera for wide view

applications and a Cognex camera in its wrist

that will eventually support many complex vision tasks.

and other

smart robots

will be getting better all the time thanks to improvements in Artificial Intelligence.

Smart Factories

Companies are incorporating many new advanced digital technologies into their

factories

Smart Factories -

'Smart factories' where products 'talk' to

each stage of the production process are the next big thing in automation.

In Germany, engineers and academics working to create this "fourth industrial

revolution" call it Industry 4.0; in the US, it's referred to as "the industrial internet"

to improve efficiency, enhance their workers skills and to stay ahead in business.

This is being pushed as

Industry 4.0

Industry 4.0 -

Almost all industrial companies have recognized this and want to

digitize their entire value chain by 2020. German industrial companies

alone are investing EUR 40 billion for this transformation.

Those who already produce digitalized products have a clear competitive advantage.

in Germany where factories become much more integrated and digital.

Airbus is one example with it’s

Factory of the Future

which allows it to produce 1.5 planes a day.

The employees use digital tools to track all elements

of the production process, they can use the virtual reality software

MiRA

Smart Factories -

'Smart factories' where products 'talk' to

each stage of the production process are the next big thing in automation.

In Germany, engineers and academics working to create this "fourth industrial

revolution" call it Industry 4.0; in the US, it's referred to as "the industrial internet"

to improve efficiency, enhance their workers skills and to stay ahead in business.

This is being pushed as

Industry 4.0

Industry 4.0 -

Almost all industrial companies have recognized this and want to

digitize their entire value chain by 2020. German industrial companies

alone are investing EUR 40 billion for this transformation.

Those who already produce digitalized products have a clear competitive advantage.

in Germany where factories become much more integrated and digital.

Airbus is one example with it’s

Factory of the Future

which allows it to produce 1.5 planes a day.

The employees use digital tools to track all elements

of the production process, they can use the virtual reality software

MiRA

Mixed Reality Application -

It is a smart, time-saving and easy-to-use tool that integrates

the digital mock-up into the production environment

by providing access to the 3D model to the people who directly work with the aircraft.

to explore new aircraft. With the use of MiRA,

inspection time for the 60,000-80,000 brackets in the A380 fuselage dropped from 3 weeks to just 3 days.

Mixed Reality Application -

It is a smart, time-saving and easy-to-use tool that integrates

the digital mock-up into the production environment

by providing access to the 3D model to the people who directly work with the aircraft.

to explore new aircraft. With the use of MiRA,

inspection time for the 60,000-80,000 brackets in the A380 fuselage dropped from 3 weeks to just 3 days.

The factory has smart workshops that has features like finger or eye-tracking,

voice control and

projecting

Augmented Reality -

While augmented reality has already begun taken a firm hold in logistics,

data glasses etc. are now starting to reach the factory floor.

Potential application simple prototyping, which allows developers to

see whether the new component fits as precisely as the CAD plans

suggest before the product is even manufactured.

work-instruction images in 3D over a structure

enables workers to operate efficiently without being encumbered.

Airbus also equips some assembly workers with Exoskeletons to help

them lift heavy loads or work in difficult spaces.

Augmented Reality -

While augmented reality has already begun taken a firm hold in logistics,

data glasses etc. are now starting to reach the factory floor.

Potential application simple prototyping, which allows developers to

see whether the new component fits as precisely as the CAD plans

suggest before the product is even manufactured.

work-instruction images in 3D over a structure

enables workers to operate efficiently without being encumbered.

Airbus also equips some assembly workers with Exoskeletons to help

them lift heavy loads or work in difficult spaces.

Airbus aims to develop industrial collaborative assistant

robots

Airbus Robots -

Airbus also plans

to introduce a new generation of humanoid robots into the factory that

can safely interact with humans where the robot is able to imitate

things they have seen, been taught or learned via demonstrations

capable

of safely interacting with humans and evolving in dynamic environments.

They are developing adaptable smart robots that can reconfigure their

task if they encounter an unexpected situation.

Airbus Group are accelerating the development of

3D printing

Airbus Robots -

Airbus also plans

to introduce a new generation of humanoid robots into the factory that

can safely interact with humans where the robot is able to imitate

things they have seen, been taught or learned via demonstrations

capable

of safely interacting with humans and evolving in dynamic environments.

They are developing adaptable smart robots that can reconfigure their

task if they encounter an unexpected situation.

Airbus Group are accelerating the development of

3D printing

Airbus 3D Printing -

3D printing can also be of great help in assembly lines to avoid outstanding work and achieve

greater efficiency in production and only 5% waste material is produced

from Additive Layer Manufacturing (ALM) on average

to produce prototypes and series components, potentially delivering cheaper and lighter parts.

Airbus 3D Printing -

3D printing can also be of great help in assembly lines to avoid outstanding work and achieve

greater efficiency in production and only 5% waste material is produced

from Additive Layer Manufacturing (ALM) on average

to produce prototypes and series components, potentially delivering cheaper and lighter parts.

Smart Delivery

Next day delivery is a huge level of convenience with Amazon Prime, they have gone

even further, customers in Manhattan can now pay to get their order in just 60 minutes,

Amazon’s

Prime Now

Prime Now -

The Prime Now offering is available initially to Manhattan residents and will be rolled

out to additional cities next year. If two hours is simply too long to wait,

customers can pay $7.99 to get their order in just 60 minutes.

offering is available initially to Manhattan residents and will

be rolled out to additional cities in 2015.

Amazon are currently testing

delivery drones

to have your parcels delivered

to you through the sky, they aim to use it to deliver packages to customers around the world in 30 minutes or less.

Prime Now -

The Prime Now offering is available initially to Manhattan residents and will be rolled

out to additional cities next year. If two hours is simply too long to wait,

customers can pay $7.99 to get their order in just 60 minutes.

offering is available initially to Manhattan residents and will

be rolled out to additional cities in 2015.

Amazon are currently testing

delivery drones

to have your parcels delivered

to you through the sky, they aim to use it to deliver packages to customers around the world in 30 minutes or less.

Amazon may also be working on 3D printing

while delivering

Print and Drive -

In a continued effort to improve the speed of its deliveries, Amazon has a new plan

– it wants to send out delivery trucks that can 3D-print objects on-demand

while on the go, in order for them to reach customers faster.

technology so your

item can be created while it’s on its way to you, speeding up the time

it takes to receive your item.

Amazon is bringing the highstreet right to your front door.

It’s likely in the future Amazon will incorporate driverless delivery cars

too as they are heavily invested in trying to automate all aspects of their business.

In 2012, Amazon purchased

Kiva

robots for $775 million to speed up time from

ordering to dispatch. They are special robots which autonomously bring items

to the human picker to save them from walking to each item.

They are also trying to automate the human picker and packer job by having a

competition

Print and Drive -

In a continued effort to improve the speed of its deliveries, Amazon has a new plan

– it wants to send out delivery trucks that can 3D-print objects on-demand

while on the go, in order for them to reach customers faster.

technology so your

item can be created while it’s on its way to you, speeding up the time

it takes to receive your item.

Amazon is bringing the highstreet right to your front door.

It’s likely in the future Amazon will incorporate driverless delivery cars

too as they are heavily invested in trying to automate all aspects of their business.

In 2012, Amazon purchased

Kiva

robots for $775 million to speed up time from

ordering to dispatch. They are special robots which autonomously bring items

to the human picker to save them from walking to each item.

They are also trying to automate the human picker and packer job by having a

competition

Robot Pickers -

Robots will use the latest computer-vision and machine-learning algorithms

to try to perform the work done by humans in vast fulfillment centers.

Amazon is organizing the event to spur the development of more nimble-fingered product-packing machines.

where teams can compete to win $25,000. Participating robots will earn points by

locating products sitting somewhere on a stack of shelves, retrieving them safely,

and then packing them into cardboard shipping boxes.

Robot Pickers -

Robots will use the latest computer-vision and machine-learning algorithms

to try to perform the work done by humans in vast fulfillment centers.

Amazon is organizing the event to spur the development of more nimble-fingered product-packing machines.

where teams can compete to win $25,000. Participating robots will earn points by

locating products sitting somewhere on a stack of shelves, retrieving them safely,

and then packing them into cardboard shipping boxes.

As production increases and labour cost's reduce due to cheaper, better robots, and as factories keep incorporating more technology to improve efficiency, combined with the option of localised manufacturing using 3D printing, will result in the reduction in the price of items and allow us to keep up with our consumption demands.

Go to top

About

Website created by

Website created by Nathan Leigh

Website tools created by Mary Lou.

Picture of my cat Kizzy on the right.